Key Characteristics and Benefits

Heat Resistance: PTFE has a high melting point (around 327°C or 621°F), which allows the film to operate at high temperatures without degrading.

Chemical Resistance: PTFE is highly resistant to most chemicals, making it suitable for use in harsh environments where other materials might degrade.

Electrical Insulation: PTFE has excellent electrical insulating properties, which ensure safe operation even at high temperatures.

Flexibility: PTFE film heaters are flexible, allowing them to be applied to surfaces of various shapes and sizes, including curved or irregular surfaces.

Durability: PTFE is a robust material that withstands wear and tear, extending the lifespan of the heater.

Construction

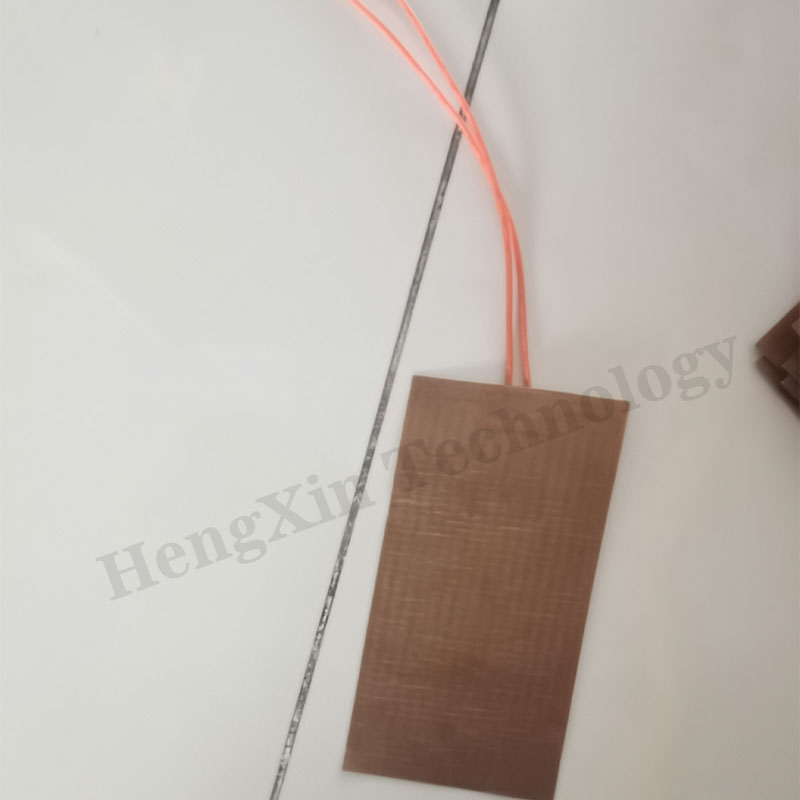

A typical PTFE film heater consists of a heating element, often made of wire or etched foil, encapsulated between layers of PTFE film. The heating element can be tailored to provide uniform heating across the surface of the film.

Applications

PTFE film heaters are used in various industries and applications, including:

Electronics: For preventing condensation or maintaining temperature in sensitive electronic components.

Medical Devices: Used in diagnostic equipment and other medical devices requiring precise temperature control.

Laboratory Equipment: Ideal for use in environments where chemical resistance and high temperatures are necessary.

Food Processing: Ensures uniform heating in applications where hygiene and chemical resistance are crucial.

Aerospace and Automotive: Used for de-icing, maintaining battery temperatures, and other applications requiring reliable and durable heating solutions.

Advantages

Non-stick Surface: PTFE’s non-stick properties make it easy to clean and maintain.

Uniform Heating: The construction allows for even heat distribution.

Customization: Can be manufactured in various sizes and shapes to fit specific applications.

Limitations

Cost: PTFE heaters can be more expensive than other types of flexible heaters due to the material and manufacturing process.

Mechanical Strength: While PTFE is durable, it is not as mechanically strong as some other materials and may require additional support in certain applications.

In summary, PTFE film heaters are versatile, high-performance heating elements ideal for demanding applications requiring chemical resistance, high-temperature operation, and flexibility.